From January to October this year, Guangdong’s industrial added value for enterprises above designated size reached 3.33 trillion yuan, a year-on-year increase of 3.6%, rising for six consecutive months; the total profits of industrial enterprises above designated size were 845.8 billion yuan, a year-on-year increase of 12.09%, achieving positive growth for five consecutive months.

Between the data, we see the efficiency; between the improvements, we see quality. From the Pearl River Delta to the east, west, and north of Guangdong, from traditional industries to emerging industries, from workshops to laboratories… Guangdong, a major manufacturing province in China, insists on prioritizing the real economy and manufacturing. It takes the realization of new industrialization as a key task of modernization construction, continuously increasing the “intelligence quotient,” “green quotient,” and “value quotient” of manufacturing, using new industries to help recreate a new Guangdong.

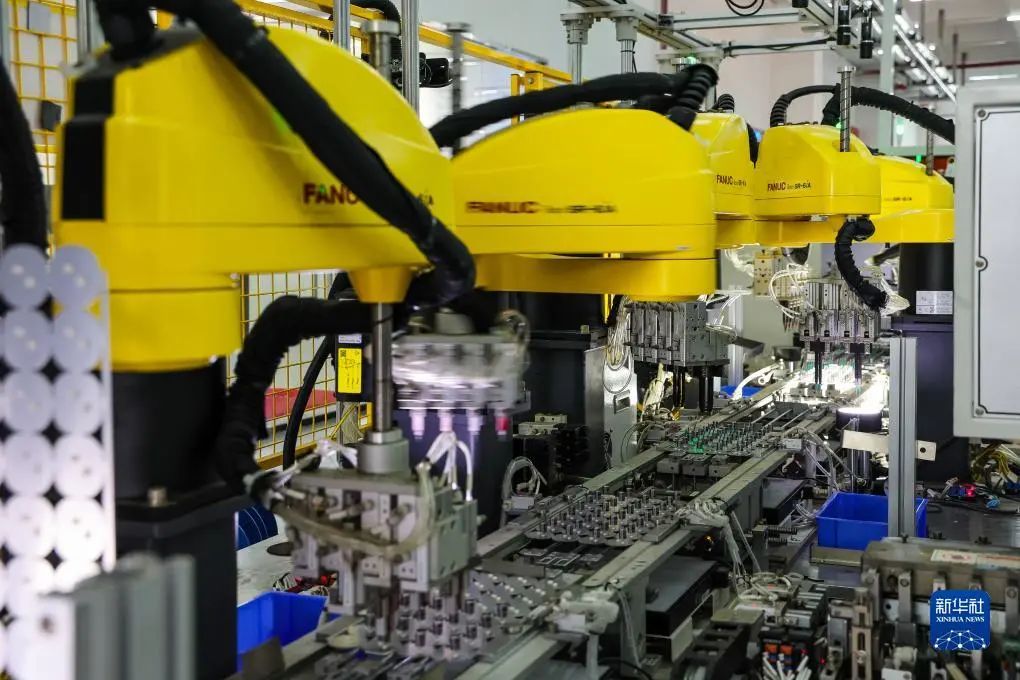

Higher “Intelligence Quotient”

Continuously promoting technological innovation and enhancing the “intelligence quotient” of manufacturing is the necessary path to drive “lean growth” and achieve high-quality development in manufacturing.

In Foshan, Guangdong, the capital of home appliances in China, factories are bustling with activity, not just with workers but also with the busy figures of robots.

In the first three quarters of this year, the leading home appliance company Midea Group achieved a revenue of 291.1 billion yuan, a year-on-year increase of 7.67%. Among this, the revenue from robotics and automation was 22.9 billion yuan, a year-on-year increase of 17%.

Continuous and relentless technological innovation has played an indispensable role. Fang Hongbo, Chairman of Midea Group, said that Midea Group actively embraces change, dares to disrupt itself and innovate boldly, driving comprehensive digitalization and intelligence, bringing significant transformative effects to Midea and improving operational quality. To date, Midea Group has built 3 “zero-carbon factories,” 5 “lighthouse factories,” and 27 “national green factories.”

Walking through the lands of Guangdong, stories of enterprises bravely innovating and transforming can be seen everywhere. Traditional industries promote the optimization and upgrading of new products, new processes, new equipment, and new materials to create century-old shops that are evergreen, while emerging and future industries actively seize the technological high ground to fight the battle for industrial chain modernization.

At the end of October this year, the “Super G Factory” of Weijing Energy Storage’s zinc-iron redox flow batteries in Fushan Industrial Park, Zhuhai, went into full production. Inside the factory, over 300 robots undertake precise and heavy tasks. With laser positioning and visual positioning technology, as well as advanced manufacturing processes such as insect bionics, robots can accurately operate to a precision of 0.1 millimeters, whether lifting 200 kilograms with a single arm or picking up thin-as-wing proton exchange membranes.

“Weijing Energy Storage has formed a research and development team consisting of intelligent manufacturing engineers, process engineers, and equipment engineers, starting from scratch, overcoming nearly 50 technical and equipment challenges, and completed the domestication of the flow battery stack from technical parameters to the industrial chain in 4 years, increasing production efficiency by tens of times,” said Liu Lei, Chief Intelligent Manufacturing Officer of Weijing Energy Storage Technology Co., Ltd.

The responsible person from the Guangdong Provincial Department of Industry and Information Technology stated that Guangdong will continue to promote the construction of a manufacturing collaborative innovation system led by enterprises and guided by industrial demand, strengthen the capability building of national manufacturing innovation centers, create a new type of energy storage national manufacturing innovation center jointly built by the ministry and province, optimize the layout of manufacturing innovation centers, enterprise technology centers, industrial design centers, and other industrial innovation platforms, and enhance the “intelligence quotient” of Guangdong’s manufacturing.

Greener “Green Quotient”

Perfecting the green manufacturing system, cultivating green low-carbon factories, green low-carbon parks, green low-carbon supply chains… Currently, Guangdong is accelerating its green transformation to create new momentum for green growth.

From the perspective of energy supply, the rapidly developing offshore wind power is injecting continuous “green energy” into the economic development of Guangdong. In Yangjiang, western Guangdong, the 2 million kilowatt wind farm built by the Three Gorges Group has generated more than 1 billion kilowatt-hours of electricity.

In Shantou, eastern Guangdong, the Lemen I offshore wind farm built by Datang Shantou Company has generated over 1.4 billion kilowatt-hours of electricity in nearly two years since its operation. Compared to traditional coal-fired power units, it can save 488,000 tons of standard coal and reduce carbon dioxide emissions by 917,000 tons.

From the perspective of enterprise production, more and more “zero-carbon factories” and “low-carbon factories” are rapidly replacing traditional high-energy-consuming and high-polluting workshops.

Midea Group’s integrated packaging and recycling service has achieved paperless processes from component production to factory delivery, saving about 350,000 cardboard boxes annually. Through “photovoltaic + energy storage” and introducing wind and nuclear power, it has achieved 100% clean electricity supply.

From the development concept, local governments are increasingly valuing the new momentum brought by green development.

Kaiping, Jiangmen, known as the “hometown of overseas Chinese,” with developed manufacturing industries such as textiles, food, and building materials, as well as being a major fishing town and tourist destination. In November this year, Kaiping was selected as one of the first batch of pilot projects for carbon peaking and carbon neutrality in Guangdong Province, becoming the only county-level city pilot on the list.

According to the person in charge of Kaiping, Kaiping and the State Power Investment Corporation have established a joint working group to promote the “dual carbon” pilot, planning and constructing clean energy supply projects, energy technology development projects, and renewable resource and agricultural and forestry waste recycling projects with a total capacity of 476,000 kilowatts, expected to produce 1.8 billion kilowatt-hours of clean electricity annually, reducing carbon dioxide emissions by 600,000 tons and driving local investment of about 5 billion yuan.

According to statistics, since this year, Guangdong’s manufacturing industry has continued to advance green production, with the unit GDP energy consumption continuously decreasing.

More “Value Quotient”

Driven by innovation and continuous industrial upgrading, Guangdong’s manufacturing enterprises have significantly improved in quality and efficiency, boosting the economy’s “value quotient.”

Entering the “210kW high-temperature fuel cell power generation system research and application demonstration project” jointly developed by Chaozhou Sanhuan (Group) Co., Ltd. and Guangdong Energy Group, fans, inverters, stacks, heat exchangers, and controllers operate within blue cabinets, with different colored pipes feeding gas and water into them for high-temperature chemical reactions to generate electricity.

“Looking back at the path Sanhuan Group has taken, we have always focused on our core business and innovation, continuously pushing for renewal, turning traditional ceramics into high-tech, high-quality, high-added-value functional ceramics, electronic ceramics, and new energy ceramics,” said Li Gang, chairman of the company. “Only through self-innovation can we continuously improve quality development and self-breakthrough, maintaining year-on-year growth in revenue and net profit.”

In the continuous push for equipment renewal, process upgrading, digital empowerment, and management innovation, many traditional industries in Guangdong have revitalized and unleashed new potential.

The fully automated intelligent production line has replaced the traditional manual process of soy sauce brewing; data detection at 494 points has replaced the craftsmanship and taste testing by masters… At Foshan Haitian Flavouring and Food Co., Ltd., the century-old traditional industry of soy sauce has embraced a new business model.

Huang Shuliang, assistant president of Haitian Flavour Industry, said that Haitian has been working on technological innovation in intelligent and digital technologies for many years, independently developing highly intelligent equipment such as tower-type disc-making equipment and fully automatic continuous soy sauce pressing equipment. Currently, the entire process is automated, increasing production efficiency by more than twice and saving costs of over 500 million yuan.

As a national pilot for comprehensive reform of manufacturing industry transformation and upgrading, Foshan has more than 5,000 industrial enterprises above designated size undergoing digital transformation, accounting for more than 50%. These enterprises that actively participate in technological upgrades have seen an average production efficiency increase of 16.5% and a product delivery cycle reduction of 20.2%.

In the first ten months of this year, Guangdong’s investment in industrial technology transformation increased by 22.3% year-on-year, 22.2 percentage points higher than the same period in 2022, the highest growth rate in five years, and above the national average.

The responsible person from the Guangdong Provincial Department of Industry and Information Technology introduced that in recent years, Guangdong has vigorously implemented five major actions such as technological transformation enterprise base training, striving to promote more than 9,000 industrial enterprises to carry out technological transformations each year. Launching the “Technological Transformation Campaign” special action, in conjunction with cities to organize actions to support and enhance, improve industrial quality and efficiency, enterprise exchange and docking, and project optimization and acceleration, with the province and cities having conducted more than 100 various activities so far.